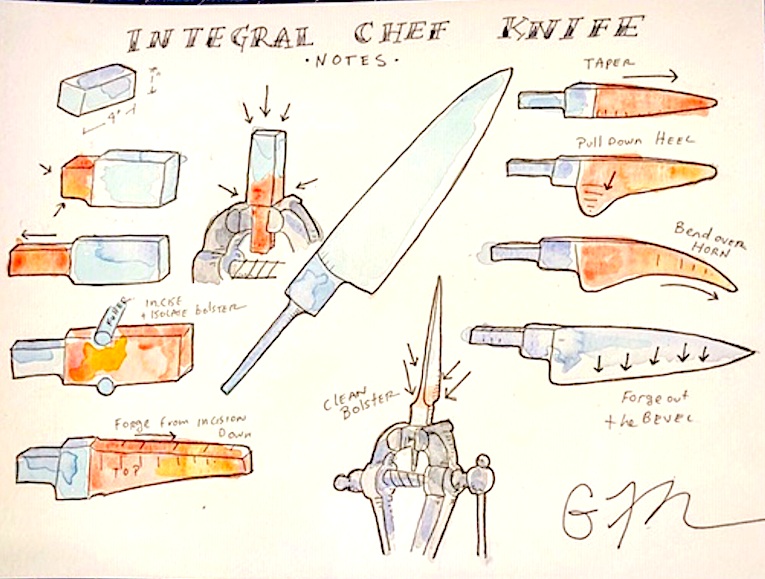

Process details on the integral knife making technique

An “integral” knife is single piece of carbon steel which is forged in a way where the bolster is integrated into the knife creating a smooth transition between the handle and the blade. These knives can only be hand forged and represent many of the elements inherent in traditional blacksmithing methods.

1

The starting pieces of an integral knife is a billet of high carbon 1084 steel measuring 1” x 1” X 4”.

2

Isolating the tenon of the knife that will eventually be the tang that will be embedded into the handle.

3

Isolating the mass in front of the bolster of the blade to create transition from the handle to the blade.

4

Forging out the mass in front of the bolster to create the length of the blade and creating the preform tip

5

Forging down the mass from the spine to create the edge. As you pull down the steel you have to compensate for the mass to push the spine up.

6

finished forging the bevel cleaning the errant hammer marks and forging the the tang to length. Next the knives will be ground to the proper geometry and then have a handle of choice fitted to them.

finished integral style knife

forge detail on integral knife